Steel Bollards for Warehouse Safety

9th Oct 2023

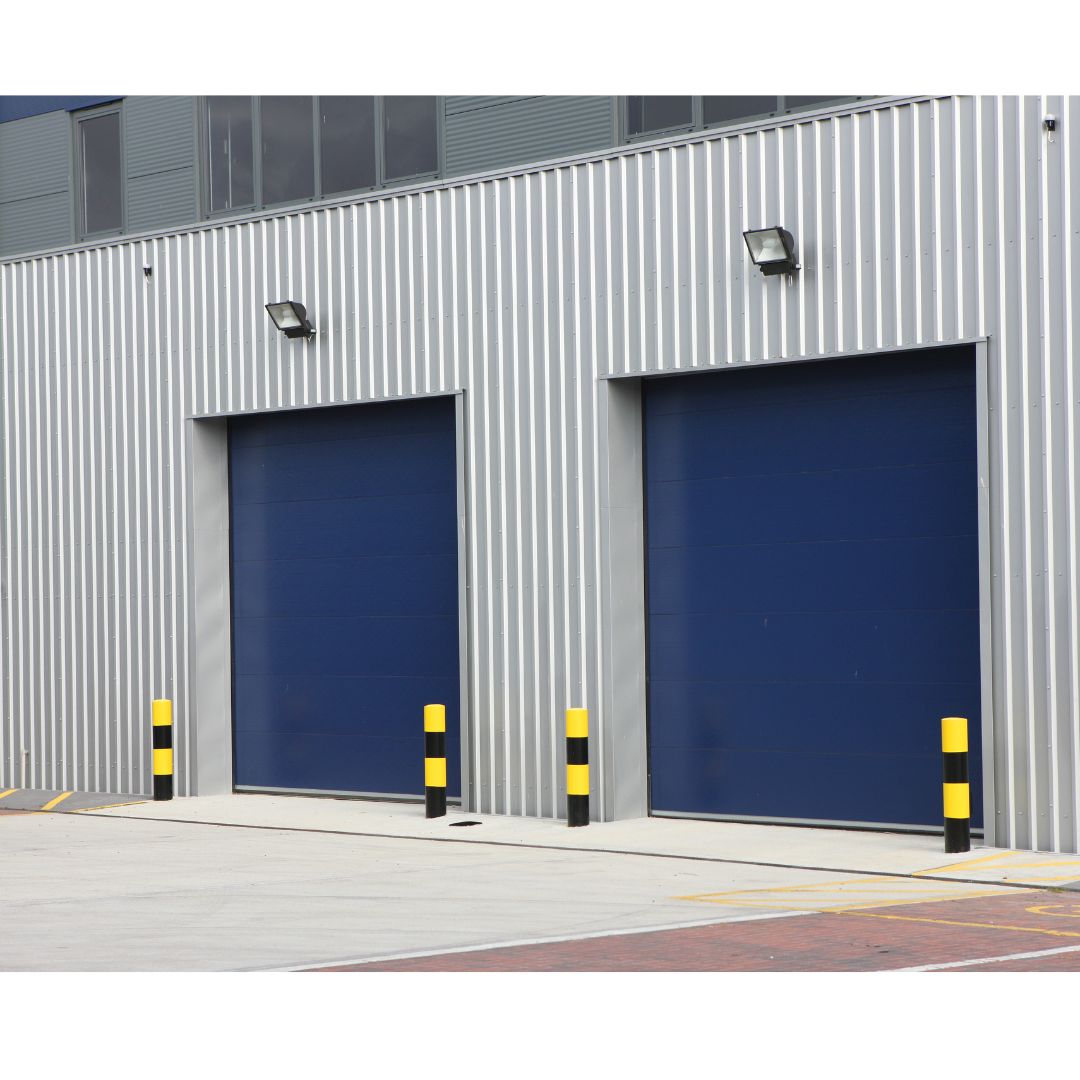

Operating a warehouse, distribution center, or manufacturing facility involves heavy machinery and equipment, making the protection of employees and assets a top priority. One highly effective means of enhancing safety is by incorporating metal bollards into your infrastructure. In this blog, we'll delve into the numerous advantages of metal bollards, including bolt-down, yellow, steel pipe, and removable options, to illustrate why these protective bollards are an indispensable investment for any material handling environment.

Enhanced Safety with Metal Bollards

Safety always takes precedence in any workplace, and metal bollards play a crucial role in achieving this goal. Among other functions, acting as a visible barrier between pedestrian areas and equipment zones, these safety bollard posts reduce the risk of accidents and collisions in high-traffic spaces. They provide a protective shield that significantly lowers the chances of equipment inadvertently straying into pedestrian pathways or other hazardous areas within a warehouse.

Unparalleled Impact Resistance

One standout advantage of metal bollards is their outstanding strength and impact resistance. Crafted from high-quality steel, these bollards can withstand considerable force without bending or collapsing. This durability ensures their continued effectiveness in shielding equipment, walls, infrastructure, and personnel from impacts caused by forklifts, pallet jacks, and other material handling equipment.

Asset Protection

Material handling equipment represents a substantial investment for any business. Metal bollards, including steel pipe bollards, act as a protective barrier for valuable machinery, racks, and other assets within your facility. By preventing accidental collisions, they contribute to prolonging the lifespan of your equipment and reducing maintenance and repair costs.

Design Flexibility

Metal bollards offer design flexibility, coming in various sizes, shapes, and styles that can seamlessly integrate with your warehouse's aesthetics and layout. Whether you prefer removeable steel bollards, bolt down bollards, or eye-catching yellow bollards, you can choose the options that best suit your specific requirements.

Effortless Installation

Installing metal bollards is a straightforward process. Depending on your needs, you can opt for surface mount bollards or those that can be embedded into concrete.

- Surface Mount Bollards: Surface mounted bollards are typically attached to the floor with concrete anchors. They are a popular choice for warehouse environments because they are relatively easy to install and can be relocated if needed.

- Bolt-Down Bollards: Bolt down bollards are a type of surface mount bollard that is secured in place by bolting them to the ground. They offer stability and can withstand impacts effectively.

- Embedded Bollards: Embedded bollards are installed by embedding them into the ground. This method provides a more permanent and robust solution but may require more effort during installation. The hole for the bollard should be at least 3 feet deep and 12 inches wider than the diameter of the bollard. The bollard should be set in the hole and surrounded with concrete.

- Removable Steel Bollards: Removable safety bollards can be removed when not in use, making them a good option for areas where bollards are not needed all the time. They are often used for temporary crowd control. Removeable bollards are typically surface mounted and attached to the floor with concrete anchors.

- Fixed Bollards: Fixed bollards are permanently installed and cannot be moved or removed easily. They are ideal for creating permanent barriers and boundaries within a warehouse.

- Flexible Steel Bollards: Flexible bollards are designed to flex upon impact, absorbing and dissipating the force. These are particularly useful in areas where occasional collisions are expected.

- Folding Bollards: Folding bollards can be folded down when not in use, making them a good option for areas where space is limited. They are also often used for temporary crowd control.

- Off-Set Bollards: Off set bollards are installed at an angle, rather than straight up and down. This makes them more effective at deflecting vehicles and other objects. Off-set safety bollards are typically embedded in concrete. The hole for the off-set bollard should be at least 3 feet deep and 12 inches wider than the diameter of the bollard. The bollard should be set in the hole at an angle and surrounded with concrete.

Exceptional Longevity

Steel, known for its durability and resistance to corrosion and wear, is the primary material used for metal bollards. Consequently, metal bollard posts have a reputation for standing the test of time, making them a wise long-term investment in your warehouse's safety infrastructure. Warehouse bollards are durable and long-lasting, saving you time and money with minimal need for frequent replacements.

Conclusion

When it comes to the safety of your employees, equipment, and assets in a material handling environment, metal bollards are a prudent choice. Steel bollards offer enhanced safety, exceptional impact resistance, asset protection, and design flexibility while being easy to install and exceptionally durable. By investing in metal bollards, you demonstrate your commitment to maintaining a secure and efficient warehouse operation.

VIEW OUR INVENTORY OF SAFETY BOLLARDS AND BOLLARD ACCESSORIES