FOB: Our Illinois Warehouse

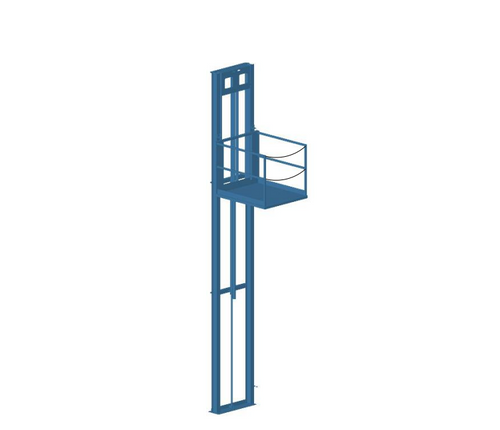

Boost your facility’s efficiency with Advance Lifts Vertical Reciprocating Conveyors (VRCs) from Material Flow. These high-performance mezzanine lift systems are engineered to move goods and materials between floors with speed, safety, and precision. Unlike scissor lifts, Advance Lifts VRCs offer custom platform sizes, fast vertical travel, and tight-space installation—perfect for demanding industrial environments.

Choose from C, Z, or L loading patterns to match your workflow, with cantilever or straddle designs that handle various weight capacities and platform sizes. Whether floor-mounted or pit-mounted, each unit delivers smooth, reliable operation across multiple levels.

Safety is built in, with double chains, mechanical locking brakes, and motors with holding brakes. All control panels are UL-listed, and every system complies with ASME B20.1 standards—so you can trust it to perform while meeting regulatory requirements.

Take your vertical material handling to the next level with Advance Lifts VRCs—engineered for performance, built for safety.

-

Platform Configurations: C, Z, or L loading patterns

-

Mounting Options: Floor-mounted or pit-mounted

-

Designs: Cantilever or straddle

-

Safety Compliance: ASME B20.1, UL-listed controllers

-

Safety Features: Double chains, locking brakes, integral holding brakes

-

Applications: Industrial multi-level material handling

-

Rider Policy: No riders allowed

-

Warranty: 5-Year Structural, 1-Year Electrical/Hydraulic

-

Operation Limit (Hydraulic VRCs): Two-level operation

-

Inspection Notes: May require elevator inspection; follow local codes

Governing Codes:

- Designed to meet ASME B20.1 standards.

- Elevator inspection may be required in some locations; installations must follow local codes.