FOB: Arkansas Warehouse

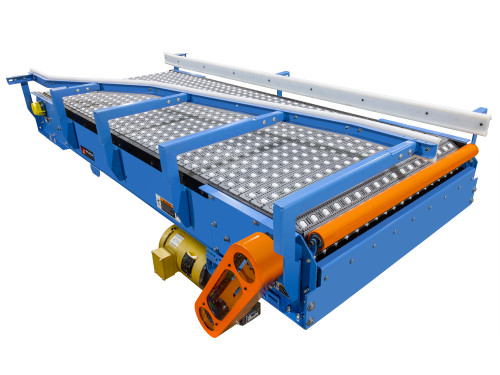

Roach 700TRT Transverse Roller Top Plastic Belt Conveyor – The Ultimate 90° Transfer Solution

When precision product handling is critical, the Roach 700TRT Transverse Roller Top Plastic Belt Conveyor from Material Flow delivers unmatched versatility and control.

Designed with a Series 400 polypropylene belt with acetal rollers and stainless steel axles, this FDA-approved conveyor is built to handle applications that demand 90° product transfer, carton rotation, merging, or centering. Whether you’re using it as a box turner or as a smooth diverter, the Roach 700TRT eliminates belt tracking issues while ensuring consistent, reliable performance.

Featuring a 7" x 1-1/2" x 10 ga. channel frame, heavy-duty bearings, UHMW wearstrips, and a constant 60 FPM belt speed, this conveyor is engineered for durability and accuracy. The 1/3 HP right-angle gear motor, catenary take-up, and precision sprockets deliver efficiency, while optional floor supports and electrical controls allow you to tailor the system to your facility’s needs.

For industries requiring sanitary design, dependable transfers, and flexible product handling, the Roach 700TRT from Material Flow is the conveyor that keeps your line moving seamlessly.

SPECIFICATIONS

-

Belting: Series 400 transverse roller top gray polypropylene with acetal rollers & stainless steel axles, FDA approved

-

Drive Sprockets: 7.8″ pitch dia., 1.5″ square bore; optional 10.1″ pitch dia., 1.5″ or 2.5″ bore

-

Tail Sprockets: 7.8″ pitch dia., 1.5″ square bore; optional 10.1″ pitch dia., 1.5″ or 2.5″ bore

-

Drive Type: End drive, one-direction operation

-

Bearings: Heavy-duty, lubricated, ball bearing units with cast iron housings

-

Bed: 7″ x 1-1/2″ x 10 ga. channel frame with open bed & UHMW wearstrips

-

Take-Up: Catenary type at discharge end

-

Return Rollers: 1.9″ dia., 16 ga. steel (model 196S), adjustable with rubber sleeves

-

Belt Speed: Constant 60 FPM

-

Motor Drive: 1/3 HP, 230/460V, 3-phase, 60Hz ODP right-angle gear motor

-

Roller Chain: #50 roller chain (1.5 HP or less), #60 chain on larger drives, chain take-up at motor base

-

Electrical Controls: Optional

-

Floor Supports: Optional