PALLET RACK - UPRIGHT FRAMES

FROM MATERIAL FLOW 1-800-338-1382

Upright Ordering Information

-

Choose uprights to suit your storage requirements:

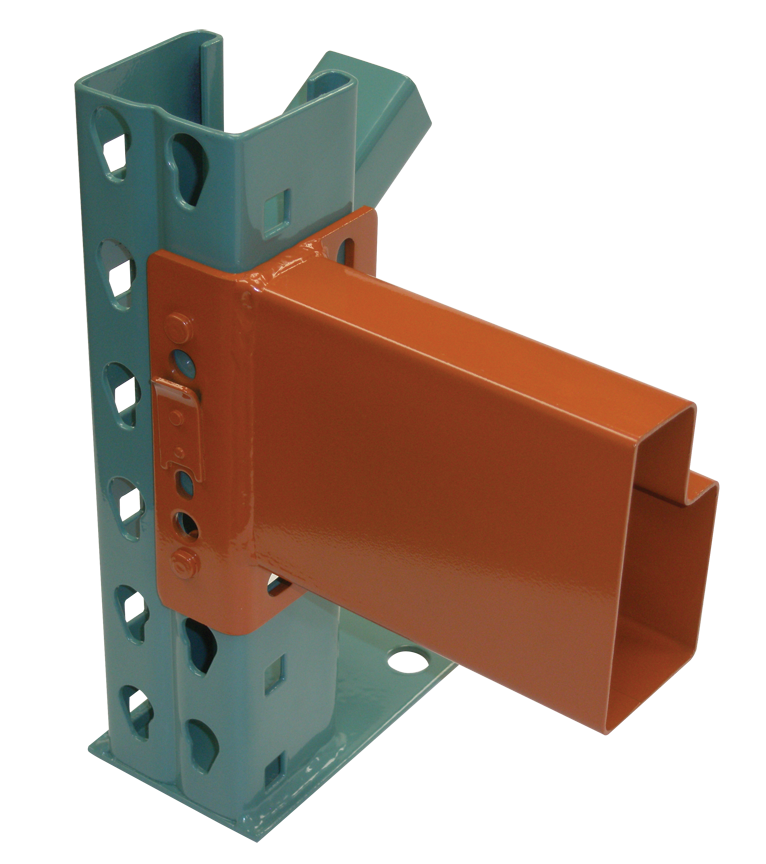

Medium-Duty - 3" x 2-1/4", 14 gauge

Heavy-Duty - 3" x 3", 13 gauge

-

Two frames are required per bay, and any number may be joined together in continuous row applications

-

Available in Lake Green

Uprights conform to the latest standards set by Rack Manufacturers' Institute LRFD Specifications.

Unique Design - Roll formed upright provides greater strength-to-weight ratio. Minimum-sized slots mean more steel per upright. Upright's structures are 100% mig-welded with precision K-brace and heavy-duty cross channel reinforcement for increased strength, rigidity and resistance to abuse.

Easy Adjustment - Tapered keyhole slots on 2" centers, provide quick, easy vertical adjustment of beams. There are no "dead spots" or obstructions in upright posts to impede movement of beam along the entire height.

Interchangeable - Lyon pallet rack fits with other traditional teardrop designs. That means you can upgrade damaged, weak, or worn out uprights and beams with our versatile rack. No need to change your whole system.

Step 1

Select Upright Frames

-

Compute total frame capacity needed to satisfy your load requirements. (Weight of heaviest pallet X number of pallets per level) X number of beam levels = total frame capacity

-

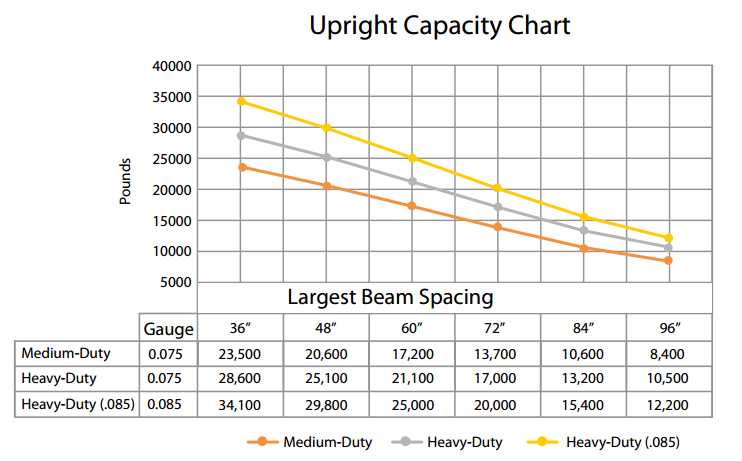

Determine "Largest Beam Spacing". Vertical distance between floor and first beam level or vertical distance between beam spacing; whichever is greater.

-

Refer to the Upright Capacity Chart. Find the "Largest Beam Spacing" number that closest resembles the number determined in Step 2. Move down the table to the desired capacity required. This will identify if the upright is Medium or Heavy-Duty.

-

Using the required depth and height of the upright for the corresponding type identified in Step 3, select the appropriate catalog number from the table.

Largest Beam Spacing has a significant impact on the capacity rating of an upright.

| Frame Height | Capacity per pair | 36" Deep Cat. No. | 42" Deep Cat. No. | 48" Deep Cat. No. | Gauge |

|---|

| 96" |

20,600 lbs. |

36M096 |

42M096 |

48M096 |

.075 |

| 120" |

20,600 lbs. |

36M120 |

42M120 |

48M120 |

.075 |

| 144" |

20,600 lbs. |

36M144 |

42M144 |

48M144 |

.075 |

| 192" |

25,100 lbs. |

- |

42H192 |

48H192 |

.075 |

| 240" |

29,800 lbs. |

- |

42H240 |

48H240 |

.085 |

FROM MATERIAL FLOW 1-800-338-1382

Beam Ordering Information

-

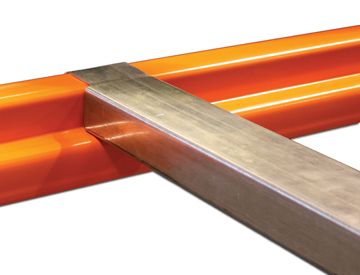

Roll-formed beams feature an integrated 1⅝" step for decking and are totally enclosed for clean applications

-

Heavy-duty rivet-type connectors engage upright wedge slots for increased holding power

-

Beams are easy to install, take down and relocate

-

Available in Safety Orange

Three-Point Safety Catch - Each beam has 3 rugged studs (4 on heavy-duty) that engage the tapered keyhole slots in the upright with a compression fit. Integral safety lock automatically locks into place when beam is properly seated.

Step 2

Beams 120" long and greater should be tied together with at least one front-to-back support except when solid decking panels are used.

Beams conform to the standards set by the latest Rack Manufacturers' Institute LRFD Specifications.

Select Beams

-

Determine load weights per pair of beams.

(Two 2,500 lb. pallet loads = 5,000 lb. beam capacity).

-

Determine length of beam required based on load width and minimum clearances.

(Minimum clearance between pallet and upright is 4", or for two 48" pallets, a total of 12". Use 108" beam).

-

Refer to desired beam length and move across table to rated capacities.

(For 108" beam and 5,000 lb. load, select beam B6500108).

| Clear Span | Capacity per pair | Beam-Face Height | Cat. No. |

|---|

| 96" |

5,200 lbs. |

4.1" |

N96 |

| 96" |

8,330 lbs. |

5" |

S96 |

| 108" |

6,320 lbs. |

4.65" |

N108 |

| 108" |

9,940 lbs. |

6" |

S108 |

| 120" |

6,140 lbs. |

5" |

N120 |

| 120" |

8,920 lbs. |

6" |

S120 |

| 144" |

6,790 lbs. |

6" |

N144 |

| 144" |

9,370 lbs. |

6.5" |

S144 |

Step 3

Select Decking

Solid Decking Panels

Solid Decking Panels

Heavy, 14-gauge panels feature three 3" x 1⅝" x 14-gauge hat channels welded to the underside for maximum strength and durability. Panels drop into place to provide a solid deck surface.

| W x D | Capacity | Cat. No. |

|---|

|

Solid Decking Panels

|

| 48" x 30" |

11,865 lbs. |

DP4830 |

| 60" x 30" |

11,865 lbs. |

DP6030 |

| 48" x 36" |

8,247 lbs. |

DP4836 |

| 60" x 36" |

8,247 lbs. |

DP6036 |

| 48" x 42" |

6,057 lbs. |

DP4842 |

| 60" x 42" |

6,057 lbs. |

DP6042 |

| 48" x 48" |

5,198 lbs. |

DP4848 |

| 60" x 48" |

5,198 lbs. |

DP6048 |

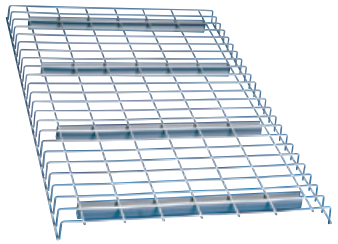

Wire Decking

Wire Decking

Heavy-duty waterfall decking features a 2½" x 4" 6-gauge wire mesh with 14-gauge steel channels for safe, durable storage and ease of installation. Meets all fire and safety regulations. Available in Frost Gray.

| Wire decking sizes necessary to fit Lyon pallet rack |

|---|

| Beam Width | Wire Decking Sizes |

|---|

| 90" |

(2) 44"W |

| 96" |

(2) 46"W |

| 102" |

(1) 46"W and (1) 52"W |

| 108" |

(2) 52"W |

| 120" |

(2) 58"W |

| 144" |

(3) 46"W |

| W x D | # Channels | Capacity | Cat. No. |

|---|

|

Wire Decking

|

| 46" x 30" |

3 |

3,000 lbs. |

WD4630H |

| 52" x 30" |

3 |

3,000 lbs. |

WD5230H |

| 44" x 36" |

3 |

3,000 lbs. |

WD4436H |

| 46" x 36" |

3 |

3,000 lbs. |

WD4636H |

| 52" x 36" |

3 |

3,000 lbs. |

WD5236H |

| 58" x 36" |

3 |

3,000 lbs. |

WD5836H |

| 46" x 42" |

4 |

3,000 lbs. |

WD4642H |

| 46" x 42" |

3 |

2,500 lbs. |

WD4642L |

| 52" x 42" |

4 |

3,000 lbs. |

WD5242H |

| 52" x 42" |

3 |

2,500 lbs. |

WD5242L |

| 58" x 42" |

4 |

3,000 lbs. |

WD5842H |

| 58" x 42" |

3 |

2,500 lbs. |

WD5842L |

| 44" x 48" |

3 |

2,250 lbs. |

WD4448L |

| 46" x 48" |

4 |

2,800 lbs. |

WD4648H |

| 46" x 48" |

3 |

2,250 lbs. |

WD4648L |

| 52" x 48" |

4 |

2,800 lbs. |

WD5248H |

| 52" x 48" |

3 |

2,250 lbs. |

WD5248L |

| 58" x 48" |

3 |

2,250 lbs. |

WD5848L |

PALLET RACK - ACCESSORIES

FROM MATERIAL FLOW 1-800-338-1382

Step 4

Select Accessories

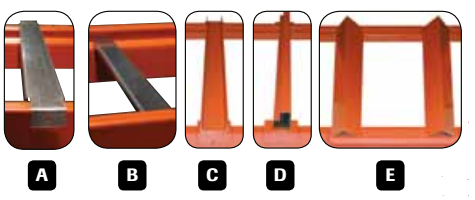

(A) Front-to-Back Support

Reduces the likelihood of inaccurately placed pallets falling through.

(B) Plywood Support Channel

To support plywood or other decking material, or as front-to-back member between beams.

(C) Skid Support

Provides secure, easily adjustable base for skid runners.

(D) Fork Entry Bar

Solid base and proper fork clearance for non-palletized loads.

(E) Drum Cradle

For safe storage of cylindrical items. Welded unit fits securely on beams.

| Dimension | Capacity | Cat. No. |

|---|

|

Front-to-Back Support

|

| 36" Deep |

1,840 lbs. |

FBSUP36 |

| 42" Deep |

1,540 lbs. |

FBSUP42 |

| 48" Deep |

1,320 lbs. |

FBSUP48 |

|

Plywood Support Channel

|

| 36" Deep |

730 lbs. |

PWSUP36 |

| 42" Deep |

610 lbs. |

PWSUP42 |

| 48" Deep |

530 lbs. |

PWSUP48 |

|

Skid Support

|

| 36" Deep |

650 lbs. |

SKSUP36 |

| 42" Deep |

550 lbs. |

SKSUP42 |

| 48" Deep |

475 lbs. |

SKSUP48 |

|

Fork Entry Bar

|

| 36" Deep |

7000 lbs. |

FEBAR36 |

| 42" Deep |

6000 lbs. |

FEBAR42 |

| 36" Deep |

5000 lbs. |

FEBAR48 |

|

Drum Cradle

|

| 36" Deep |

3750 lbs. |

DRCD36 |

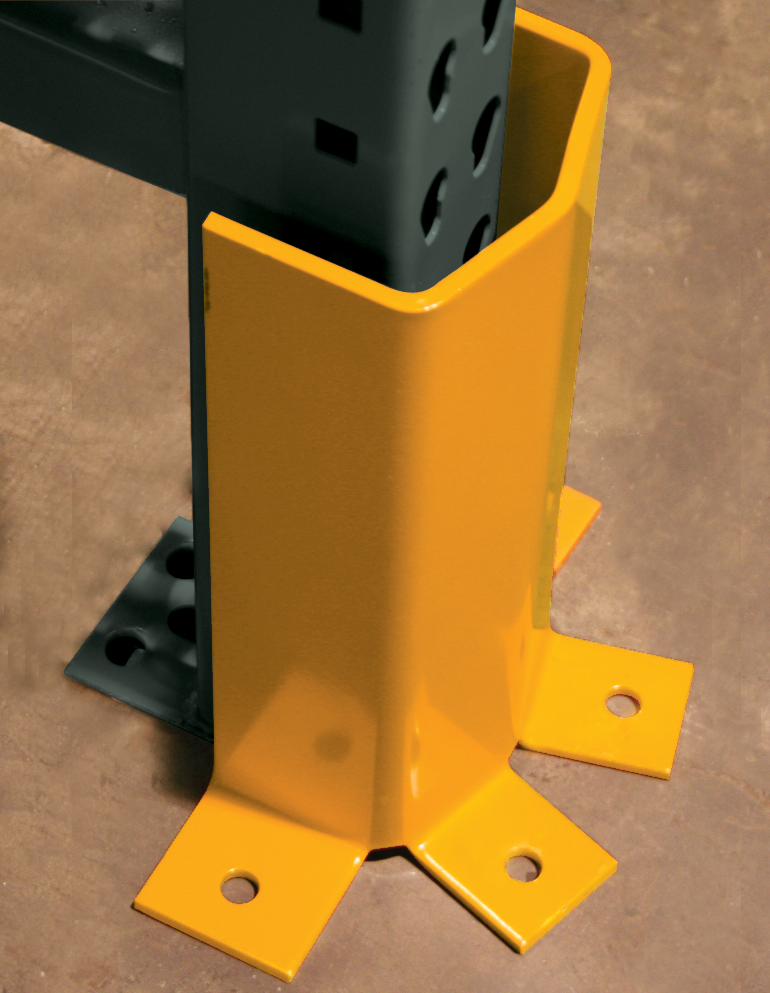

(F) Impact Support

Provides extra protection against abuse. Bolt on the floor only. Finish is Safety Yellow.

No. IMSUP12 - 12" high

No. IMSUP24 - 24" high

No. IMSUP36 - 36" high

No. IMSUP48 - 48" high

Upright Anchor

Optional wedge-type anchor can be used to secure column posts. ½" dia. x 3¾" long.

No. 25163

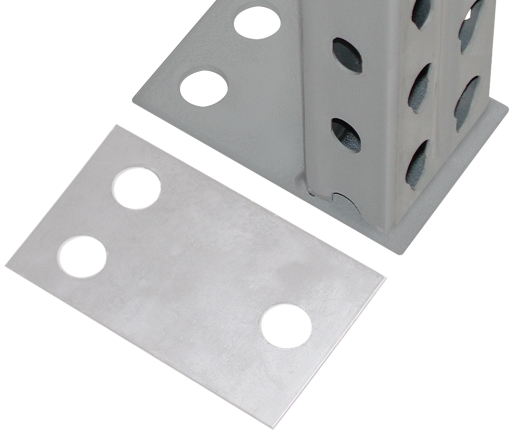

(G) Shim Plate

Nests under footplate. Unpainted.

No. FLSH34

(H), (I) Row Spacers & Wall Ties

Row spacer provides a stabilizing connection for back-to-back rows of racks; wall ties provide stability and consistent spacing from the wall. Galvanized construction resists rust and corrosion. Two spacers recommended for each pair of uprights. Bolts included.

| Dimension | Cat. No. |

|---|

|

Row Spacer

|

| 4" |

RSPC04 |

| 6" |

RSPC06 |

| 8" |

RSPC08 |

| 10" |

RSPC10 |

| 12" |

RSPC12 |

| 18" |

RSPC18 |

|

Wall Tie

|

| 4" |

WSPC04 |

| 6" |

WSPC06 |

| 8" |

WSPC08 |

| 10" |

WSPC10 |

| 12" |

WSPC12 |

| 18" |

WSPC18 |

NOTE: Load-carrying capacities for individual accessories listed are based on evenly distributed loads and are limited by the support capacity of the beams and/or upright assemblies. When skid supports, fork-entry bars and/or front-to-back supports are used to support the load, the weight is not evenly distributed to the beam and, therefore, beam capacities are reduced significantly.