Roll into 2025 with Confidence: The Ultimate Guide to Choosing the Right Industrial Casters

4th Nov 2024

Welcome to the dynamic world of industrial mobility, where choosing the right caster can make all the difference in optimizing your operations. As 2025 approaches, the variety of caster options available on the market has expanded, catering to ever more specialized and demanding applications. Whether you're outfitting heavy machinery, streamlining food service operations, or ensuring precise movement in manufacturing, selecting the correct caster is crucial. This guide from MaterialFlow.com dives deep into the nuances of caster selection, offering insights into everything from brake casters and kingpinless models to heavy-duty and maintenance-free options. We'll help you understand the key features that matter, making it easier for you to roll forward with confidence in any industry.

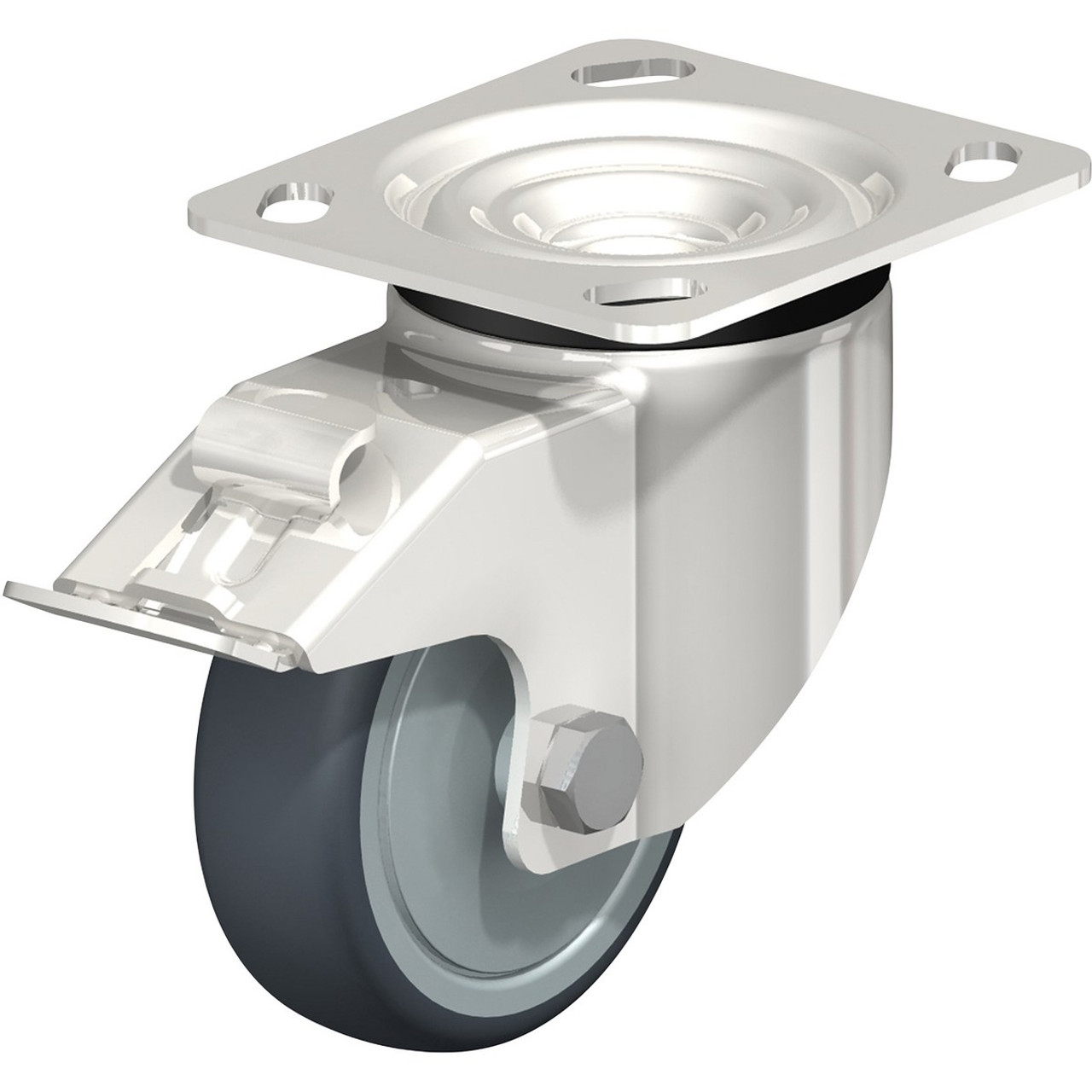

1. CA6 Series Casters with Swivel Lock Brakes

Introduction: Enhance the mobility and safety of your equipment with the CA6 Series Casters featuring swivel lock brakes...

Pros:

- Precision Control: Swivel lock feature allows for precise maneuverability and stationary control.

- Versatile Applications: Suitable for a variety of environments including workshops, hospitals, and retail spaces.

- Safety: Locking brakes enhance safety by preventing unintended movement.

Cons:

- Cost: May be more expensive than standard casters without lock brakes.

- Complexity: Additional locking mechanism may require more maintenance.

2. STP5200 Light Medium Duty Food Service Swivel Stem Casters

Introduction: The STP5200 series provides light to medium-duty casters specifically tailored for the food service industry...

Pros:

- Hygiene: Specifically designed for environments where cleanliness is crucial, such as food service areas.

- Ease of Use: Swivel stem design allows for effortless maneuvering around tight corners.

- Durability: Built to withstand the daily rigors of food service environments.

Cons:

- Load Limitation: Light to medium duty, not suitable for very heavy loads.

- Specialization: Primarily designed for food service, may not be ideal for industrial applications.

3. STP7200 KPL Series Heavy Duty Kingpinless Swivel Casters

Introduction: Built to withstand the rigors of demanding industrial environments, the STP7200 KPL Series features heavy-duty kingpinless swivel casters...

Pros:

- Enhanced Durability: Kingpinless design eliminates the weak point in traditional casters, increasing longevity.

- Smooth Operation: Offers more fluid swivel action under heavy loads.

- Load Capacity: Suitable for heavy-duty applications requiring robust support.

Cons:

- Cost: Higher cost due to advanced design and durability features.

- Weight: Typically heavier, which might be challenging to maneuver in some scenarios.

4. STP6805 MFS Series Maintenance-Free Shock-Absorbing Rigid Casters

Introduction: The STP6805 MFS Series offers maintenance-free, shock-absorbing rigid casters, ideal for applications that require the reduction of vibrations and noise...

Pros:

- Maintenance-Free: Designed to function without the need for regular maintenance.

- Shock Absorption: Reduces vibrations, making it ideal for sensitive equipment transport.

- Noise Reduction: Quieter operation compared to standard rigid casters.

Cons:

- Flexibility: Rigid design limits maneuverability compared to swivel casters.

- Application Specific: Best used where shock absorption is a priority, may not be necessary for all environments.

5. STP7600 Series Super Heavy Duty Rigid and Swivel Casters

- STP7600 Series Super Heavy Duty Rigid Casters

- STP7600 Series Super Heavy Duty Swivel Casters

- More Heavy Duty Casters

Introduction: The STP7600 Series is the pinnacle of heavy-duty caster solutions, offering both rigid and swivel options to accommodate the most demanding industrial applications...

Pros:

- High Load Capacity: Capable of handling extremely heavy loads, ideal for industrial applications.

- Durable Construction: Designed to withstand tough, heavy-duty use.

- Option Variety: Available in both rigid and swivel types to suit different needs.

Cons:

- Weight and Size: These casters are large and heavy, which might not be practical for all spaces.

- Investment: Higher initial investment due to their heavy-duty nature and durability.

6. Hamilton Casters Series BC Combination Brake Casters

Introduction: The Hamilton Casters Series BC Combination Brake Casters offer precise control and enhanced safety features suitable for various applications...

Pros:

- Dual locking mechanism enhances safety by preventing unwanted movement.

- Available in various sizes to accommodate different load capacities.

- Robust construction ensures long-term durability.

Cons:

- Higher price point due to advanced braking system.

- May be over-engineered for applications requiring simple mobility solutions.

7. Vestil Stainless Steel Thermoplastic Rubber-Elastomer Casters

Introduction: Designed for environments where cleanliness and load management are paramount, the Vestil Stainless Steel Thermoplastic Rubber-Elastomer Casters provide a hygienic and non-marking solution...

Pros:

- Non-marking and chemically resistant materials suitable for clean rooms and food services.

- Stainless steel frame offers high durability and resistance to corrosion.

- Provides smooth maneuverability with thermoplastic rubber wheels.

Cons:

- More expensive than traditional rubber casters.

- The specialized design might limit general-purpose use.

8. Vestil Extra Heavy Duty Kingpinless Casters

Introduction: Built to withstand the toughest industrial challenges, Vestil's Extra Heavy Duty Kingpinless Casters eliminate the central kingpin...

Pros:

- Kingpinless design enhances durability and impact resistance.

- Suitable for very heavy industrial applications.

- Ensures smoother swivel action and longevity.

Cons:

- Significantly heavier and more costly than standard casters.

- May require more robust equipment frames to install.

9. Hamilton Casters Series 300 General Utility Casters

Introduction: The Hamilton Casters Series 300 General Utility Casters are designed for a wide range of applications...

Pros:

- Maintenance-free design reduces downtime and upkeep costs.

- Versatile for use in a variety of settings and applications.

- Constructed for durability and smooth rolling performance.

Cons:

- Not suitable for extremely heavy loads or severe operating conditions.

- General utility design may not meet specialized application needs.

10. Hamilton Caster Series MD Maxi-Duty Casters

Introduction: Hamilton's Series MD Maxi-Duty Casters are engineered for the most demanding applications...

Pros:

- Exceptional load-bearing capacity ideal for heavy industrial use.

- Durable construction ensures long-lasting performance.

- Available in various wheel materials to suit specific flooring conditions.

Cons:

- High cost reflects their heavy-duty design.

- Significant weight of the casters may limit their use to specific environments.

Navigating the vast landscape of caster options doesn't have to be overwhelming. With the insights and tips provided in this guide, you’re well-equipped to make an informed decision that aligns with your specific operational needs. Whether you prioritize durability, maneuverability, load capacity, or maintenance ease, there’s a caster solution out there that fits the bill. Remember, the right caster not only enhances the efficiency of your operations but also plays a critical role in safety and productivity. Invest the time to choose wisely and ensure that your material handling solutions are rolling smoothly and efficiently. Thank you for turning to MaterialFlow.com for your caster needs—where every turn and roll supports your business goals in 2025 and beyond!