Find the Perfect Fit: Exploring Cantilever Racking Options for every Storage Need!

20th Nov 2024

In the diverse world of warehouse management and industrial storage, finding the right cantilever racking system can be pivotal in optimizing space and improving operational efficiency. Whether you are dealing with heavy-duty industrial items, medium-weight materials, or need specialized storage solutions, there is a cantilever rack that fits every requirement. This blog explores a variety of cantilever racking systems offered by MaterialFlow.com, including options from trusted brands like Vestil, Meco Omaha, and Little Giant. We delve into structural, medium-duty, and mobile setups, as well as unique galvanized and custom configurations, providing you with insights to make the most informed decision for your storage needs.

STRUCTURAL:

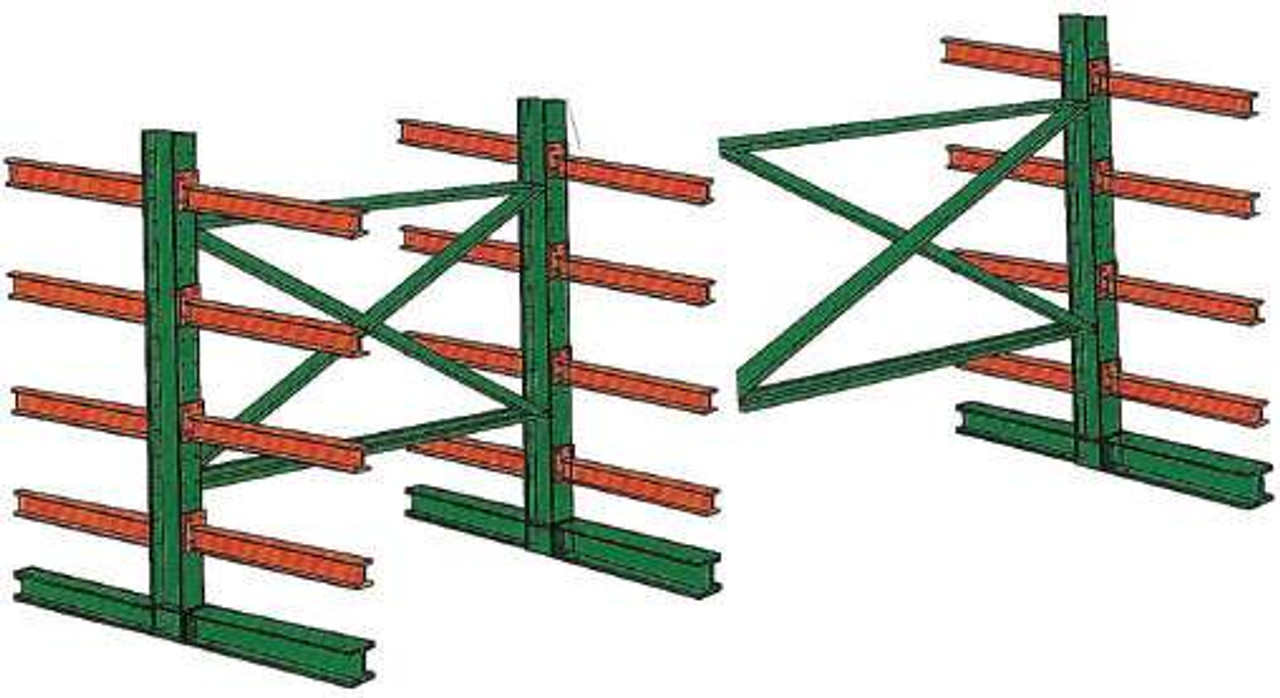

Material Flow Structural Cantilever Racking

Material Flow Structural Cantilever Racking Designed to handle heavy and bulky items, Material Flow's Structural Cantilever Racking systems are engineered for strength and versatility. These racks are perfect for storing lumber, pipes, and other long or awkwardly shaped items, providing easy access and efficient organization.

- Material Flow Structural Cantilever Racking

- Pros:

- Robust construction ideal for heavy and irregularly shaped items.

- Double-sided access improves material handling efficiency.

- Designed for durability and long-term use.

- Cons:

- Requires significant floor space.

- Higher cost due to its heavy-duty nature.

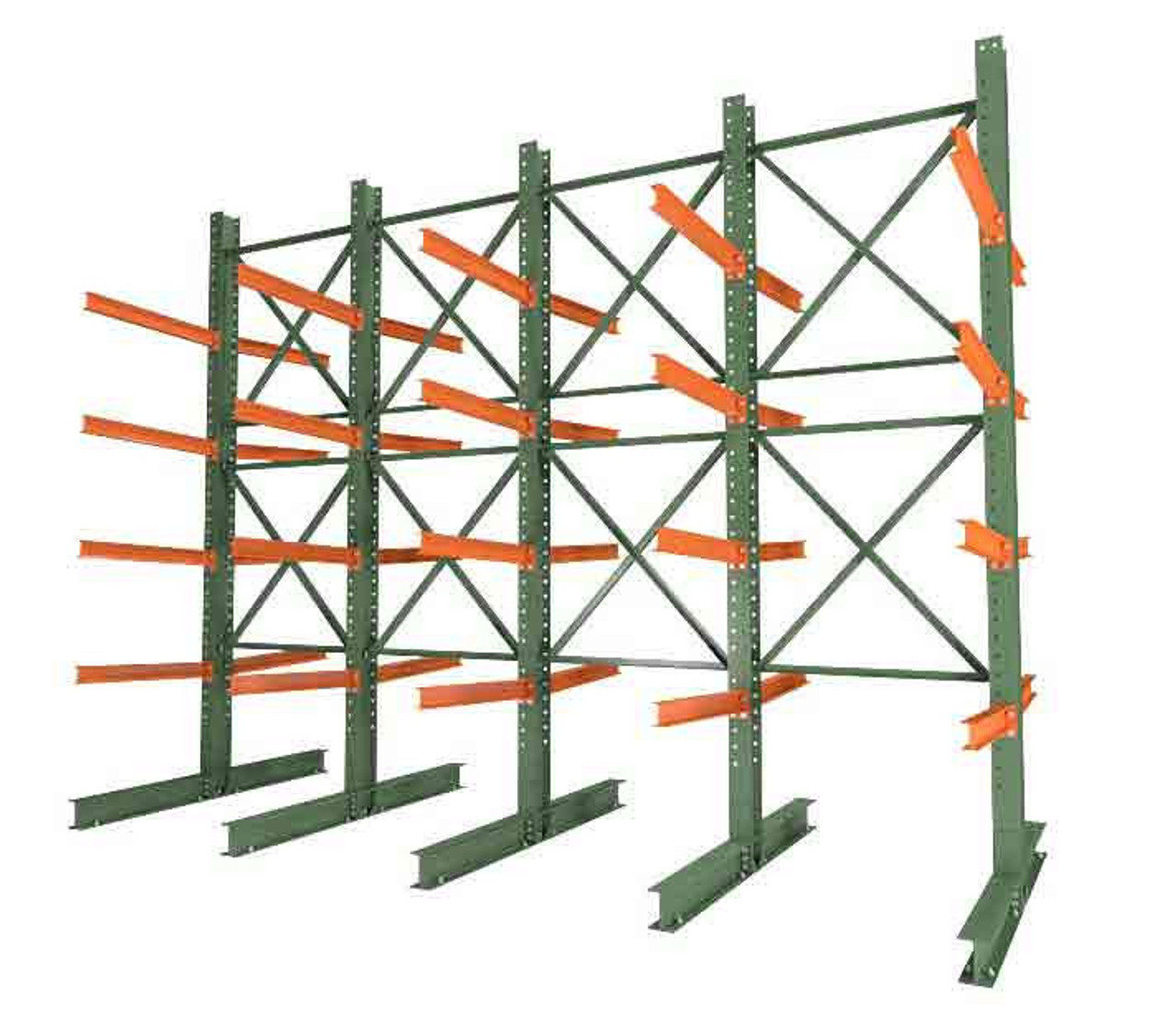

Other Brand - Vestil Structural Cantilever Racking

Vestil's Structural Cantilever Racking offers robust and reliable storage solutions for various industrial applications. With a focus on durability, these racks are crafted to support substantial weights and accommodate a range of material sizes.

Other Brand - Vestil Structural Cantilever Racking

- Vestil Structural Cantilever Racking

- Pros:

- Sturdy design suitable for industrial applications.

- Vestil brand reliability and quality assurance.

- Cons:

- Limited customization compared to Material Flow options.

- Can be more expensive due to brand premium.

MEDIUM DUTY:

Material Flow Medium Duty Cantilever Rack Material Flow's Medium Duty Cantilever Racks are ideal for warehouses and shops that require flexible storage for medium-weight materials. These racks are designed to be both sturdy and adaptable, making them suitable for a wide array of storage needs.

Material Flow Medium Duty Cantilever Rack

- Material Flow Medium Duty Cantilever Rack

- Pros:

- Versatile for a variety of medium-weight materials.

- Adjustable arms for different size loads.

- Cons:

- Not suitable for very heavy or bulky items.

- May require additional accessories for optimal organization.

Other Brand – Meco Omaha Series 1000 Medium Duty Cantilever Racks

Other Brand – Meco Omaha Series 1000 Medium Duty Cantilever Racks Meco Omaha’s Series 1000 Medium Duty Cantilever Racks are tailored for storing moderately heavy materials in retail, industrial, or manufacturing settings. These racks combine functionality with durability, offering a reliable storage solution.

- Series 1000 Medium Duty Cantilever Racks

- Pros:

- Good balance between strength and flexibility.

- Known brand with a reliable track record.

- Cons:

- Slightly less robust than heavy-duty options.

- Limited load capacity compared to structural racks.

CANTILEVER UPRIGHT FRAMES:

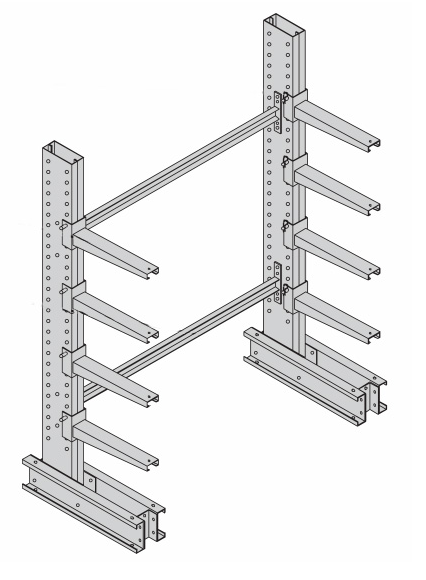

Material Flow Upright Frames Material Flow Upright Frames are crafted to offer support and stability to cantilever racking systems. These frames serve as the backbone of the rack, designed to accommodate flexibility in the arm layout and load capacities.

Material Flow Upright Frames

- Material Flow Upright Frames

- Pros:

- High-quality materials for long-lasting support.

- Easily integrated into existing racking systems.

- Cons:

- Configuration may be limited by preset designs.

- Requires careful installation for stability.

Other Brand – Meco Omaha

Other Brand – Meco Omaha Meco Omaha offers robust upright frames for cantilever racks, enhancing the structural integrity and versatility of your storage system. These frames are suitable for various applications, providing strong support for assorted load requirements.

- Meco Omaha Upright Frames

- Pros:

- Solid construction for medium to heavy loads.

- Versatility in setup with various height and arm options.

- Cons:

- Can be costlier due to brand and build quality.

- May not match existing non-brand-specific setups.

SPECIALTY TYPES:

Mobile Cantilever Racks: Little Giant Mobile Cantilever Racks

Mobile Cantilever Racks: Little Giant Mobile Cantilever Racks Little Giant Mobile Cantilever Racks bring exceptional mobility to heavy-duty storage. These racks are designed to be moved easily around the workspace, offering flexibility and efficiency in material handling and storage.

- Little Giant Mobile Cantilever Racks

- Pros:

- Mobility allows for easy reconfiguration of storage spaces.

- Ideal for dynamic workshop environments.

- Cons:

- Limited load capacity due to mobility features.

- Potential stability issues if not properly loaded.

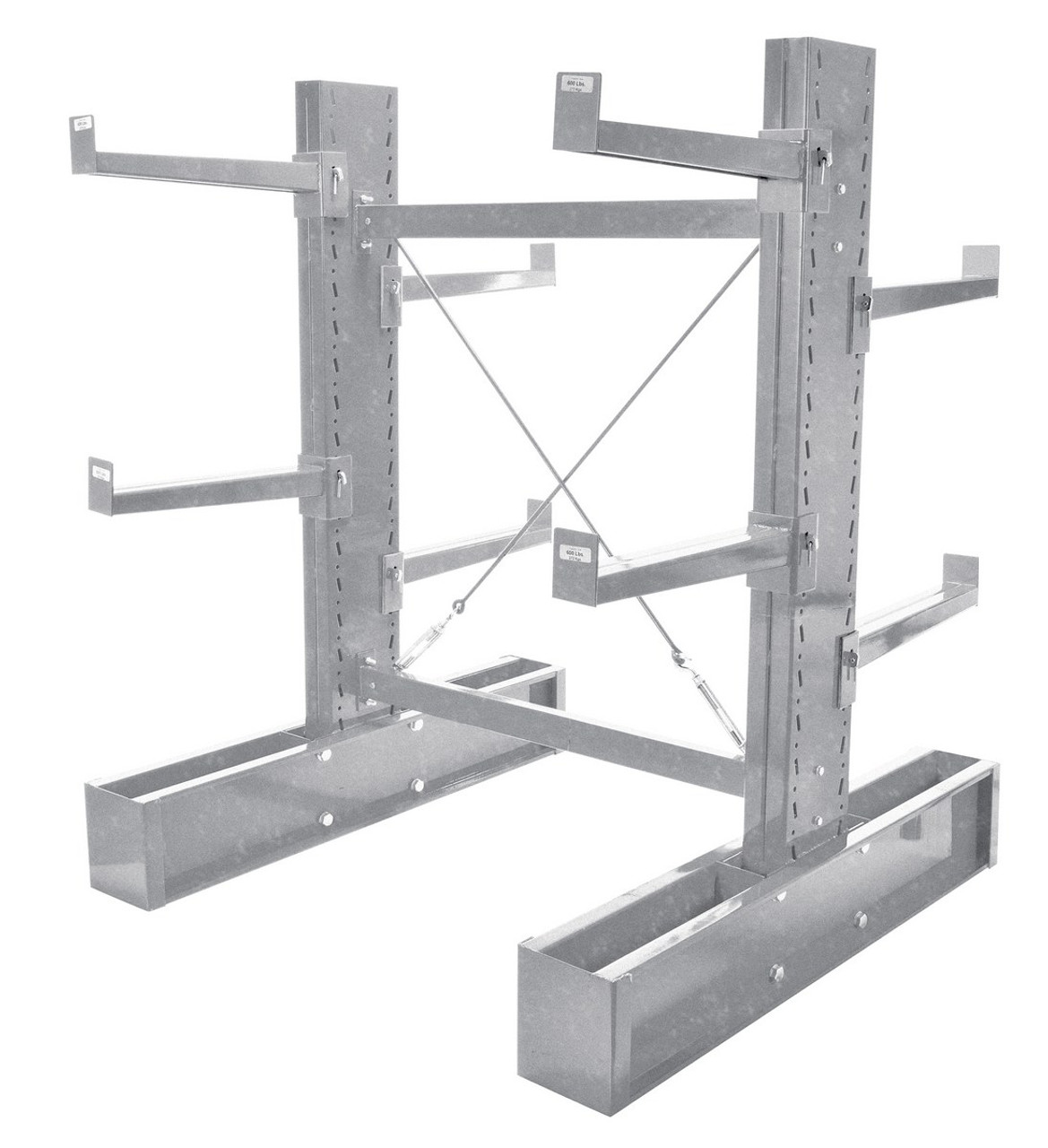

Galvanized Cantilever Racks:

Galvanized Cantilever Racks: Vestil and Red Steel offer galvanized cantilever racks that provide excellent resistance to rust and corrosion, making them ideal for both indoor and outdoor use. These racks are particularly suitable for harsh environments where durability is critical.

- Vestil Galvanized Cantilever Rack Kits

- Red Steel Galvanized Cantilever Racks

- Pros:

- Corrosion resistance suitable for outdoor or harsh environments.

- Long-term durability and maintenance-free.

- Cons:

- Higher upfront cost due to galvanization.

- Somewhat limited modification options due to fixed galvanized coating.

Custom Cantilever Racking through Material Flow:

Custom Cantilever Racking through Material Flow: Material Flow provides custom cantilever racking solutions tailored to meet specific storage needs. These racks are designed with unique specifications in mind, ensuring that every component fits perfectly for optimized storage efficiency.

- Custom Cantilever Racking

- Pros:

- Tailored to specific needs and dimensions.

- Flexibility in design and functionality.

- Cons:

- Higher cost due to customization.

- Longer lead times for manufacturing and delivery.

Heavy Duty Cantilever Racking: Jarke by SPG, Steeltree Series Heavy Duty Cantilever Racking

Heavy Duty Cantilever Racking: Jarke by SPG, Steeltree Series Jarke by SPG’s Steeltree Series represents the pinnacle of heavy-duty cantilever racking. These systems are designed to hold the heaviest loads, suitable for industrial environments where maximum capacity and durability are necessary.

- Steeltree Series Heavy Duty Cantilever Racking

- Pros:

- Extremely robust for the heaviest loads.

- Designed for industrial-scale storage needs.

- Cons:

- Significant investment in terms of space and cost.

- Not suitable for smaller or lighter storage needs.

Choosing the right cantilever racking system requires a thoughtful understanding of your current and future storage needs. From the robustness of heavy-duty racks designed for industrial applications to the flexibility of mobile and customizable options, each type of racking offers distinct benefits and potential drawbacks. By considering the specific requirements of your operations—whether you need the corrosion resistance of galvanized racks or the load-bearing capacity of structural racks—you can select a solution that not only maximizes space but also enhances safety and accessibility. Remember, the right investment in cantilever racking can significantly boost your operational efficiency and ensure a smoother workflow. Visit MaterialFlow.com to explore a wide range of reliable and high-quality cantilever racking systems that cater to all your industrial storage needs.