Efficient Material Handling: Cantilever Racks & FIFO

18th Sep 2023

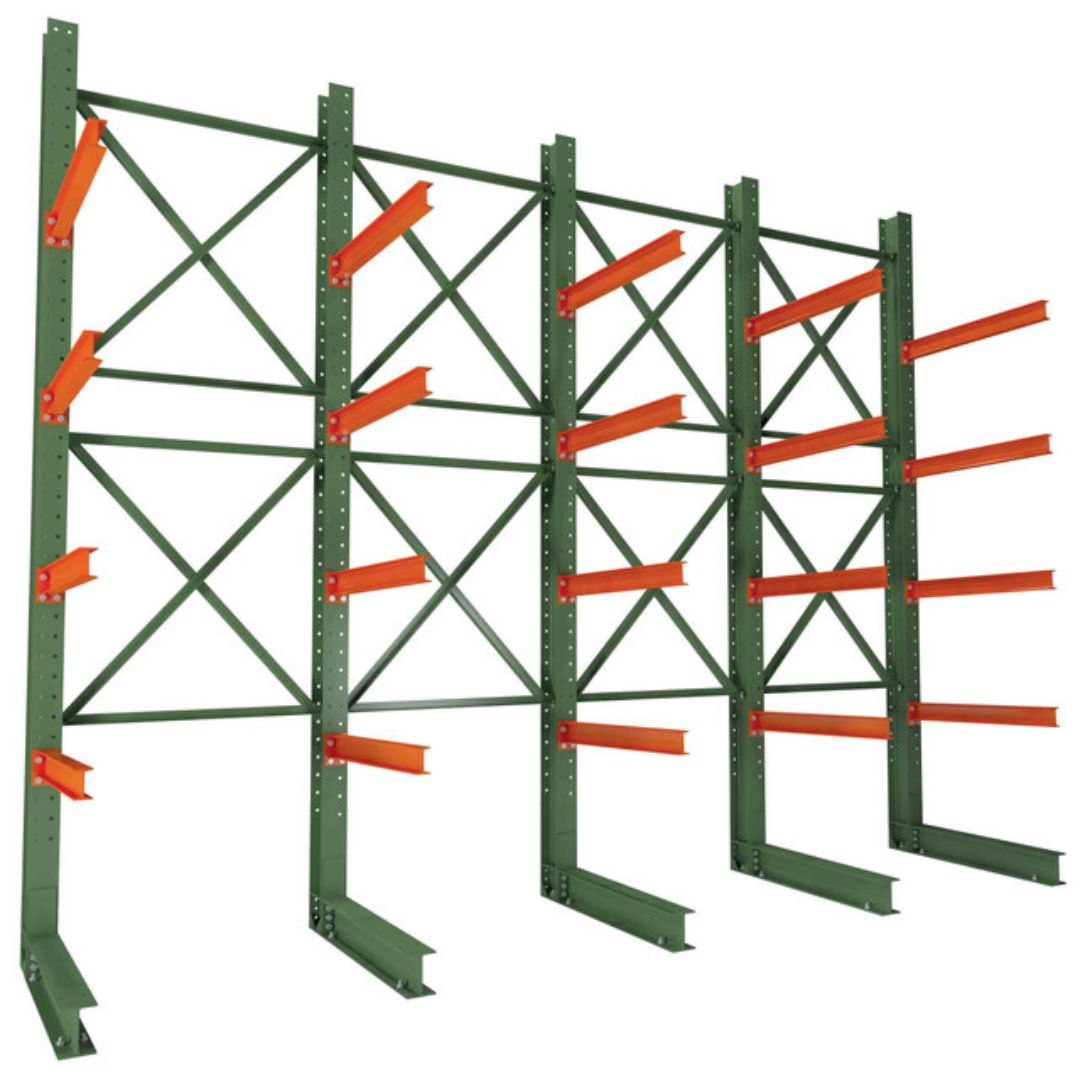

Efficient material handling systems are essential in various industries, and the use of cantilever racks has revolutionized how businesses manage their inventory. Cantilever racks offer several advantages, especially when paired with the First-In-First-Out (FIFO) inventory method. In this blog, we will explore the application of cantilever racks in three distinct industries - lumber, plumbing, and automotive - and how these industries utilize precision material handling equipment to adhere to the First In First Out method for enhanced inventory system efficiency.

Cantilever Racks and FIFO Method in the Lumber Industry

The lumber industry deals with vast quantities of long, heavy, and irregularly shaped materials. Cantilever racks are ideal for storing lumber because of their flexibility and accessibility. A few examples of how cantilever racks benefit the lumber industry include:

The lumber industry deals with vast quantities of long, heavy, and irregularly shaped materials. Cantilever racks are ideal for storing lumber because of their flexibility and accessibility. A few examples of how cantilever racks benefit the lumber industry include:

- Efficient Space Utilization: Cantilever racks allow lumber yards to maximize vertical storage space, optimizing the use of their available square footage.

- Easy Accessibility: Lumber can be accessed quickly and without the need to move other materials, thanks to the open design of cantilever racks.

- FIFO Implementation: In the lumber industry, adhering to FIFO is crucial to prevent stock from becoming obsolete. Cantilever racks facilitate the FIFO inventory method by ensuring the oldest materials are easily accessible at the front.

- Reduced Handling Costs: Minimized handling and easy access to inventory can reduce labor costs and minimize the risk of damage to the lumber during retrieval.

Cantilever Racks and FIFO Method in the Plumbing Industry

The plumbing industry relies on a wide range of materials and components, many of which are lengthy and require efficient storage solutions. A few examples of how cantilever racks are advantageous in the plumbing industry include:

- Specialized Storage: Cantilever racks can be configured to accommodate various pipe lengths, fittings, and fixtures, allowing plumbing suppliers to store their inventory more efficiently.

- FIFO Compliance: Utilizing the FIFO (First-In, First-Out) method for storing plumbing materials enables businesses to prioritize the use of older items, thereby minimizing the chances of items becoming outdated.

- Improved Order Fulfillment: Quick access to materials helps plumbing supply companies fulfill orders faster which can greatly enhance customer satisfaction.

- Reduced Damage: The industrial design of cantilever racks minimizes the risk of damage to delicate plumbing components during handling.

Cantilever Racks and FIFO Method in the Automotive Industry

The automotive industry relies on the timely availability of parts and components to maintain efficient production lines. A few ways that cantilever racks offer advantages in this context include:

- Storage of Long Parts: Many automotive components, such as exhaust pipes, bumpers, and axles, can be lengthy. Cantilever racks provide an efficient solution for storing these oddly-shaped items.

- FIFO for Components: Implementing FIFO ensures that older parts are used before newer ones, therefore reducing the risk of product waste.

- Space Optimization: Cantilever racks help maximize floor space, allowing automotive manufacturers to store a wide range of parts without overcrowding their facilities.

- Streamlined Operations: Quick access to parts and components facilitates just-in-time manufacturing processes and contributes to the reduction of production delays.

Implementing FIFO Inventory Method with Cantilever Racks

In all three industries, the FIFO method is critical for efficient inventory management. The First In First Out inventory method ensures that older materials are used first, reducing the risk of product loss. Additionally, cantilever racks support FIFO by making it easier to access and rotate inventory items. A few ways that businesses can achieve FIFO adherence are:

1. Labeling and tracking inventory with clear date markers.

1. Labeling and tracking inventory with clear date markers.

2. Training employees to follow FIFO principles during material handling operations.

3. Regularly auditing inventory to identify and address any deviations from FIFO guidelines.

Cantilever racks have become indispensable tools in the lumber, plumbing, and automotive industries, allowing businesses to efficiently store and access their inventory. When combined with the FIFO inventory method, these racks ensure that materials are used in the order they are received, thus reducing waste and improving overall operational efficiency. Whether you are managing inventories of lumber, plumbing supplies, or automotive components, cantilever racks offer a practical solution for optimizing material handling and maintaining a well-organized and cost-effective inventory management system.

BROWSE OUR LUMBER STORAGE INVENTORY